PT. Nagasakti Kurnia Textile Mill's

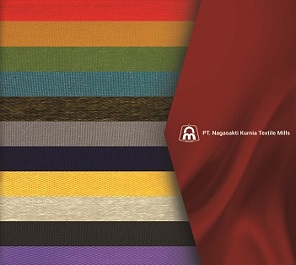

Founded in 1982, Nagasakti Kurnia Textile Mills is a leading textile manufacturer specializing in the production of high quality uniform and suiting fabrics.

As a vertically integrated operation encompassing both Weaving and Dyeing-Finishing divisions, the company stands as an example of the new generation of modern textile manufacturers in Indonesia, renowned for its use of the latest technology to cater to the needs of local garment producers as well as tapping in opportunities on the international stage through value added fabrics.